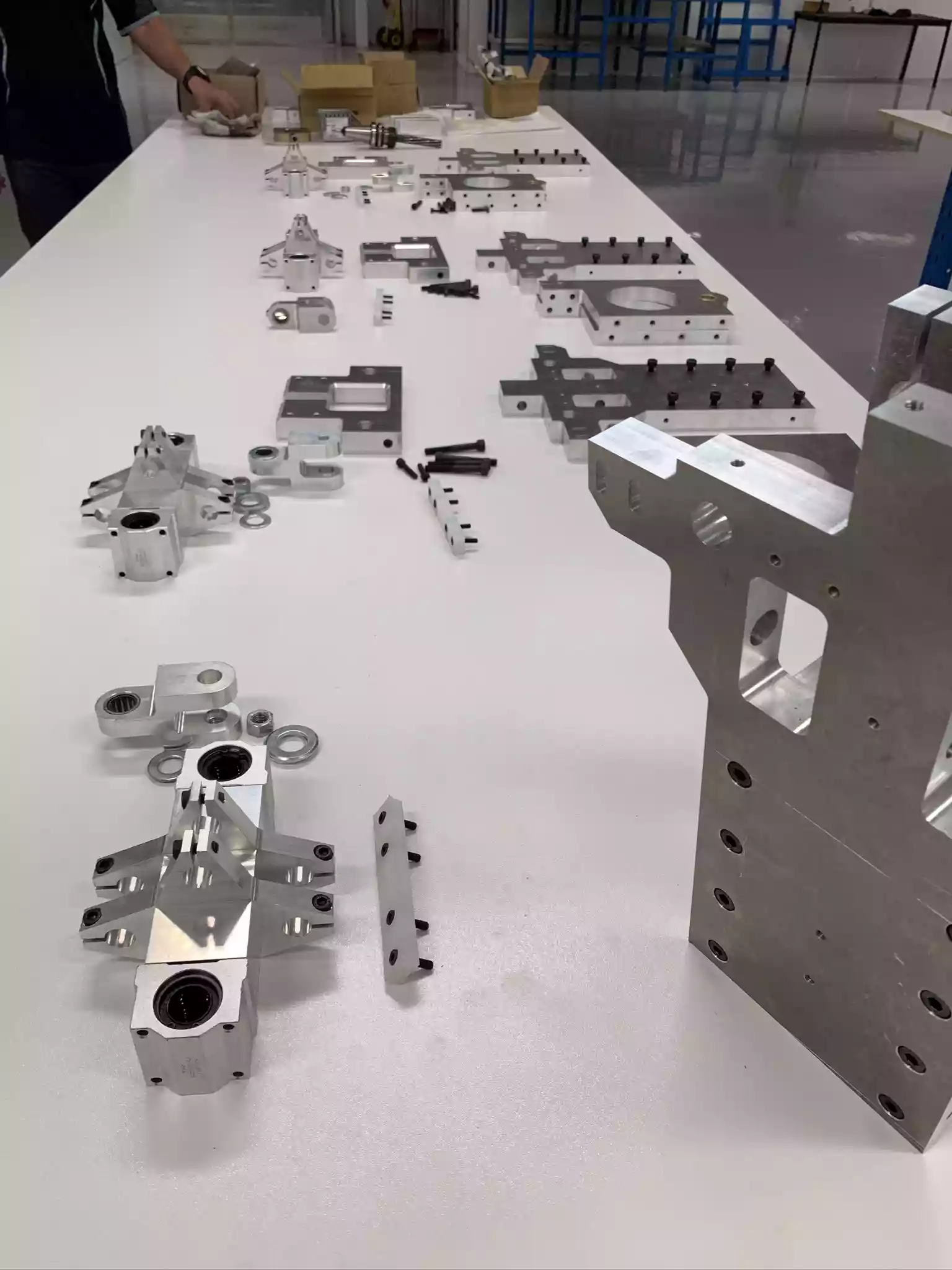

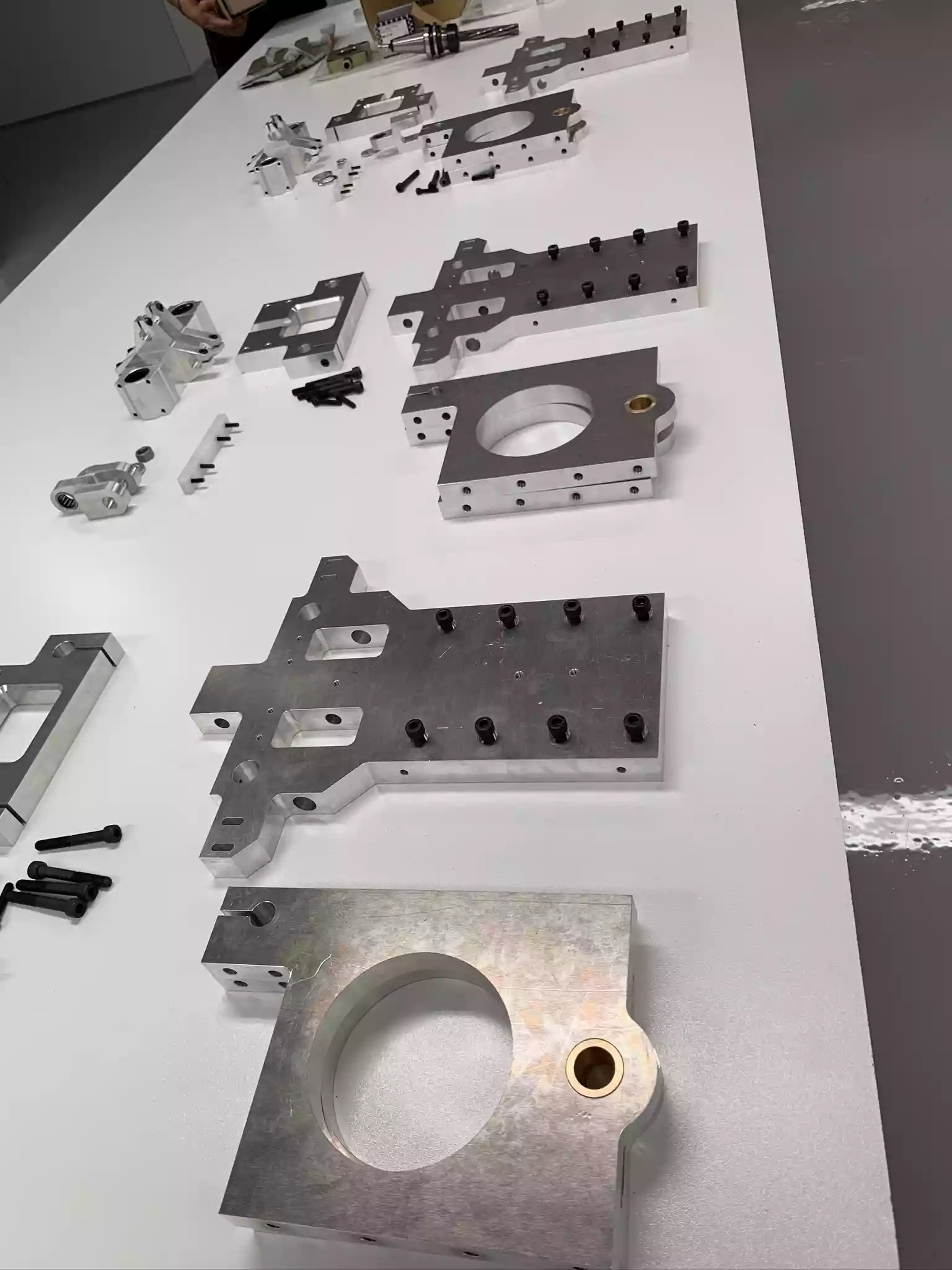

Assembly and Sub-Assemblies

Shine provides a comprehensive assembly service that enables our customers to reduce costs and maintain significantly shorter lead-times.

Our assembly team has years of experience and this is one of the areas where we rely on the integrity and knowledge of our staff to perform these tasks to the highest standards.

Along with traditional hand skills developed over many years and an eye for detail, our multi skilled workforce takes a great pride in the quality of their workmanship.

Assemblies and Sub-Assemblies are project managed within the framework of the company’s quality procedures and in accordance with client and industry specific practices and document control if required.

We are constantly striving for innovative practices, within our assembly department.

Applications can range from simple heli-coil insert assembly to large and complex special purpose equipment assemblies.

Our 400m2 clean room complies with Foreign Object Damage control and reduces risk of product failure.

Shine’s assembly processes presently:

- Helicoil inserts, locking and free running

- Nutserts, Clinch nuts, Surface Mount Nuts, Standoffs, Captive Panel Screws, and many other associated fasteners

- Sealants, Loctite, Primers, Silicone and Adhesive sealing as per customer specifications

- Bearing, Bushing, Riveting, Ground Stud installation

- Potting for electrical assemblies

- Labelling